Manufacturer for Food Blister Packaging Machines - Model SGP-200 Automatic In-Line Capper – Aligned

Manufacturer for Food Blister Packaging Machines - Model SGP-200 Automatic In-Line Capper – Aligned Detail:

● SGP In-Line Capper is suitable for capping various kinds of vessels (round type, flat type, square type) and widely used in such fields as pharmaceutical, foods, chemistry, etc.

The machine works reliably and operates easily. When a bottle already filled with materials enters the entry of the main machine, the cap drops through the cap feeder rail and covers the bottle. After that, the bottle covered by the cap enters the bottle clamp system, clamped by two belts and sent forward. Simultaneously three pairs of capping wheels fasten the caps. The capped the bottle then detaches from the bottle clamping belt and goes into the next process. For different types of bottles, users may only need to adjust the cap drop lane, bottle clamping belt, the distance between the capping wheels and the height of the working box.

|

Model |

SGP-200 |

|

Capacity |

50-100 bottles/minute depend on your bottle |

|

Cap Diameter |

Φ 25-Φ 70mm |

|

Vessel Diameter |

Φ 35-Φ 140mm |

|

Vessel Height |

3P AC 380V 50-60 Hz |

|

Power Consumption |

1.2 KW |

|

Main Machine Dimensions (L × W × H) |

1300 × 850 × 1400mm |

|

Main Machine Weight |

600Kg |

|

Cap Dropper Dimensions (L × W × H) |

1100 × 1200 × 2150 mm |

|

Cap Dropper Weight |

190kg |

With the continuous enrichment of various products, the utilization rate of bottle capping machines has also become higher. Whether it is the food industry, daily chemical industry or the pharmaceutical industry, any bottled product that wants to be packaged and sealed must be screwed. Cover operation.

Rotary capping machine, also known as capping machine, capping machine or capping machine, is a device for screwing and unscrewing the caps of plastic bottles and glass bottles (molded bottles or tube bottles) after sub-packaging. The capping machine is generally used for the aluminum cap or aluminum plastic cap crimping and sealing equipment after the antibiotic powder injection glass bottle (molded bottle or tube bottle) is filled.

The bottle caps are stored in the lower hopper and transferred to the capping bin through the frequency conversion lifting belt. After the cap is sorted, the cap is supplied to the capping head from the unloading channel, and the cap is locked during the movement of multiple capping heads. The capping is just right.

Main part:

The whole machine adopts PLC control;

The main motor is a variable frequency stepless speed regulation motor;

The outer frame of the fuselage is made of stainless steel 304, which meets GMP requirements.

Cover part

The upper cover part adopts a stepped lifting belt, the bottle cover feeding speed is fast, and the noise is low;

The falling cover structure is exquisite, and there is no reverse cover to slide off;

The upper cover adopts the method of frequency conversion speed regulation.

Screw cap part

The cap is screwed with a magnetic rotating head, and the capping torque is adjusted by magnetic adjustment. The capping qualification rate is high and the noise is low.

Rejection device

Automatically detect and reject unqualified products with bad screw caps, no aluminum foil, and no caps.

When a sudden power failure occurs, the rejection reaches the rejection position.

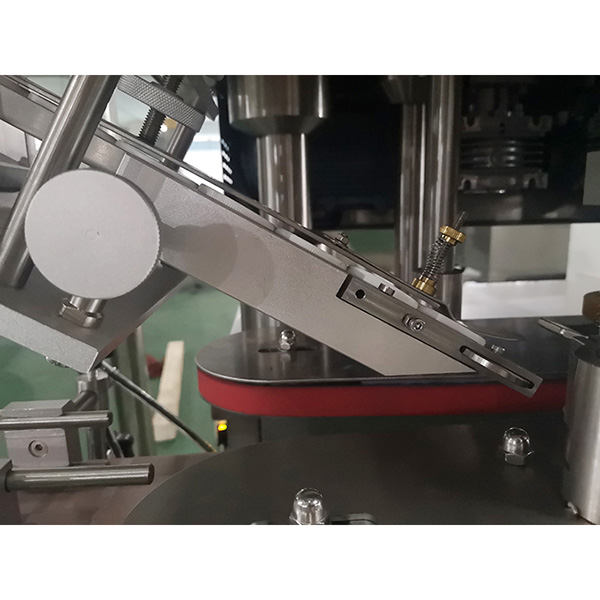

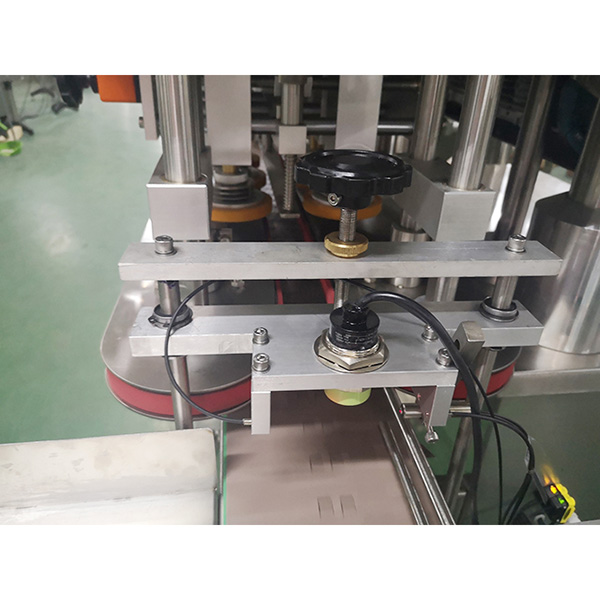

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for Manufacturer for Food Blister Packaging Machines - Model SGP-200 Automatic In-Line Capper – Aligned , The product will supply to all over the world, such as: Denver, Kyrgyzstan, California, Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of "Quality First, Customer Paramount, Sincerity and Innovation" in our mind, We have achieved great progress in the past years. Clients are welcomed to buy our standard products, or send us requests. You will be impressed by our quality and price. Please contact us now!

By Steven from Qatar - 2018.12.11 11:26

By Steven from Qatar - 2018.12.11 11:26

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

By Elaine from Netherlands - 2017.08.15 12:36

By Elaine from Netherlands - 2017.08.15 12:36