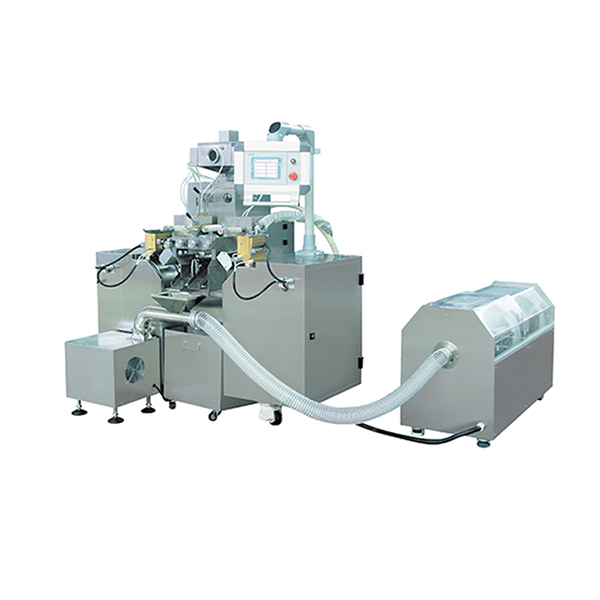

Factory Cheap Gel Cap Filler - Labeling Machine (for Round Bottle), TAPM-A Series – Aligned

Factory Cheap Gel Cap Filler - Labeling Machine (for Round Bottle), TAPM-A Series – Aligned Detail:

| Model | TAMP-A |

| Label width | 20-130mm |

| Label length | 20-200mm |

| Labeling speed | 0-100 bottles/h |

| Bottle diameter | 20-45mm or 30-70mm |

| Labeling accuracy | ±1mm |

| Operation direction | Left → Right (or Right → Left) |

1. It is suitable for round bottle labeling in the pharmaceutical, food, daily chemical and other industries, and can be used for full-circle labeling and half-circle labeling.

2. Optional automatic turntable bottle unscrambler, which can be directly connected to the front-end production line, and automatically feed bottles into the labeling machine to increase efficiency.

3. Optional configuration ribbon coding and labeling machine, which can print production date and batch number online, reduce bottle packaging procedures and improve production efficiency.

1. Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

2. Applicable products: products that require labels or films to be attached to the circumferential surface

3. Application industry: widely used in food, medicine, cosmetics, daily chemicals, electronics, hardware, plastics and other industries

4. Application examples: PET round bottle labeling, plastic bottle labeling, food cans, etc.

After the bottle-separating mechanism separates the products, the sensor detects the passing of the product and sends back a signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the product to be labeled. The labeling belt drives the product to rotate, the label is rolled, and the attaching action of a label is completed.

1. Place the product (connect to the assembly line)

2. Product delivery (automatically realized)

3. Product correction (automatically realized)

4. Product inspection (automatically realized)

5. Labeling (automatically realized)

6. Override (automatically realized)

7. Collect labeled products (connect to the subsequent packaging process)

Product detail pictures:

Related Product Guide:

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for Factory Cheap Gel Cap Filler - Labeling Machine (for Round Bottle), TAPM-A Series – Aligned , The product will supply to all over the world, such as: USA, Mombasa, French, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

By Gill from Slovenia - 2018.11.22 12:28

By Gill from Slovenia - 2018.11.22 12:28

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

By Lena from Czech republic - 2017.05.02 18:28

By Lena from Czech republic - 2017.05.02 18:28